- Tue Apr 24, 2007 6:35 pm

#6497

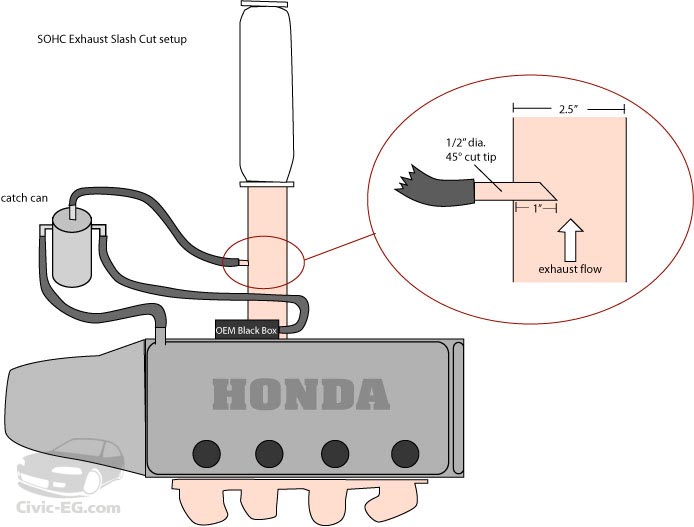

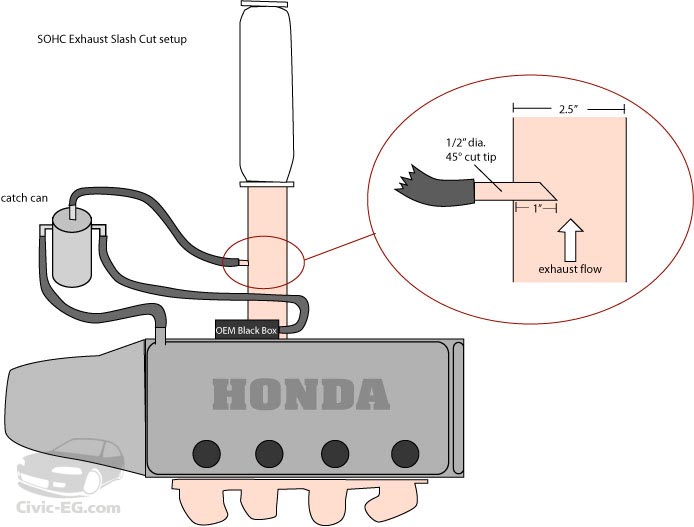

(For anyone unfamiliar with this setup, the idea is to create vacuum to vent the crank case and valve cover. When done correctly, a 45? slash cut tube placed in the exhaust will create vacuum by the Bernoulli Effect )

I'm looking into this setup and having a hard time finding good info on it...

I've read about it but want to be sure I have all the details right before I attempt... Here's a drawing:

And Here's what I've read:

- the metal "slash" tube going into the exhaust should go straight into the down pipe at a 90 degree angle.

- the slash should be at a 45 degree angle away from the exhaust flow.

I'm unsure of how far the tube should go into the down pipe?

What do you guys think about this setup?

I'm looking into this setup and having a hard time finding good info on it...

I've read about it but want to be sure I have all the details right before I attempt... Here's a drawing:

And Here's what I've read:

- the metal "slash" tube going into the exhaust should go straight into the down pipe at a 90 degree angle.

- the slash should be at a 45 degree angle away from the exhaust flow.

I'm unsure of how far the tube should go into the down pipe?

What do you guys think about this setup?

Do Not PM me your technical questions. Post them in the forum!

My 1992 SOHC Turbo Hatch

My Youtube Channel: 6th Gear Garage

My 1992 SOHC Turbo Hatch

My Youtube Channel: 6th Gear Garage

+1

+1