- Tue Jul 10, 2018 7:08 pm

#6908633

Little disclaimer for my idea of a "budget" K swap.This is a 'budget' build in the fact that I'm picking and choosing where to spend extra money for reliability.

I've done tons of swaps and installed a lot of products from different brands so I'm choosing everything I've had good experiences with in the past.

That does mean some parts aren't the most budget friendly way to install a K... but I drive 60-100 miles minimum each day so I don't want to deal with reliability issues.

Also for ease of maintenance there won't be anything tucked or shaved. I'm going to install everything as cleanly as possible while leaving everything easily serviceable in the event I need to do any repairs.

The true "budget" part of this swap is the $350 K20a base model JDM RSX engine and the K20Z3 transmission I have pieced together from 3 scrap transmissions for a total cost so far of $150. That transmission cost will go up as I order the seals and any parts I decide to replace while assembling the case.

Why K swap a car clearly not worth much more than the $200 I originally paid for it?With the suspension bushings, new rack and pinion, and stereo I've updated the car and truly enjoy driving the EG. Without including the stereo (since it can be removed and put in any of my cars) I've only got a little over $900 tied up in the car before the cost of the K swap. That $900 got me nearly 10,000 enjoyable miles of commuting to work with no unexpected issues. I knew full well the original tires on it were shot and the trans was bad. I just figured for the cost I'd drive it until they failed.

Now I like the car and figured I'd give it a second chance at life instead of sending it to the scrapyard. I'll be finishing the swap along with cleaning up the rust and putting on a nice coat of fresh paint... probably from Maaco (I'll still prep it for paint) since its a daily. But it will be better than what's there.

Also this car is really fun and compared to my TSX, this is cheaper to mess around with, the TSX has taken way longer than planned, and I miss having a fun car.

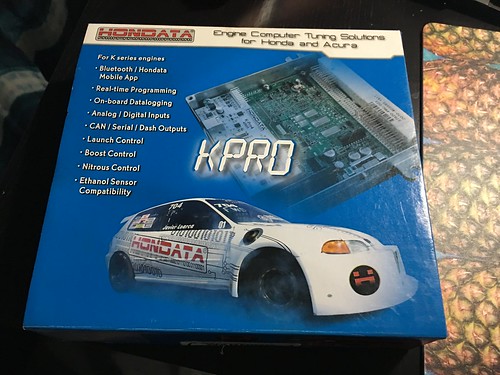

Also I'll review the parts I use so everyone can get a idea of what you get for the money. There are a lot of parts from Hybrid-Racing, Skunk2, Hondata, Honda OE, NAPA, and Karcepts.

Trans rebuilding is fun, and easier than most people think. At least the manuals... I don't know anything about the automatics.

Trans rebuilding is fun, and easier than most people think. At least the manuals... I don't know anything about the automatics.

Trans rebuilding is fun, and easier than most people think. At least the manuals... I don't know anything about the automatics.

Trans rebuilding is fun, and easier than most people think. At least the manuals... I don't know anything about the automatics.