- Thu Jul 02, 2009 4:46 pm

#127743

B18C1 Valve Lash Adjustment

I bought a 1997 GSR with 152k miles and it looks like the maintenance has been neglected. When I checked the valve clearances they were all very loose beyond spec. Tightening them all to the low side of spec is a good way to get the most performance out of the engine. According to the maintenance schedule, valve lash should be checked every 15,000 miles ~ 24,000 km.

This method guarantees that you'll get it right even if it's your first time (window-lickers excluded).

You know who you are. You ride the short bus and you're totally helpless. Please don't work on your car!

Adjust a Cold Engine

The engine has to be stone cold from sitting overnight. When you're talking about accuracy of .001 of an inch, heat deep down in a seemingly cold engine can easily throw your measurements off making your valve adjustment pointless.

Tools and Supplies

Valve Cover Gasket Kit

Honda Bond (pref'd)

Anti-seize (copper pref'd)

10mm Jam Nut Tool Alltrade/Powerbuilt 648827 $13 Amazon

Feeler Gauges .006, .007, .008 inch Craftsman Part No. 40802 $10 Sears

Ratchet

10, 12, 19mm Sockets

16mm Spark Plug Socket

Long Extension

Jack

Jack Stand

Wheel Chock

Torque Wrench capable of 7 to 80ft/lbs

Needle Nose Pliers (bent pref'd)

Torque Specs

Valve Cover Nuts 7ft/lbs

Lug Nuts 80ft/lbs

Spark Plugs 13ft/lbs

Jam Nuts

B18B

18 ft/lbs

B18C1

14 ft/lbs

Valve Clearance

B18C1

Intake .006 - .007 in

Exhaust .007 - .008 in

B18B

Intake .003 - .005 in

Exhaust .006 - .008 in

Set the parking brake. Chock a rear wheel. Loosen the lug nuts. Jack up the car and put the driver's side front on a jackstand at the jack point. Remove the wheel. You can access the crank pulley bolt with a 19mm socket and a long extension. This is how you will turn the engine by hand to tdc for each cylinder.

Please ignore my ricer brake rotors. The previous owner had them installed.

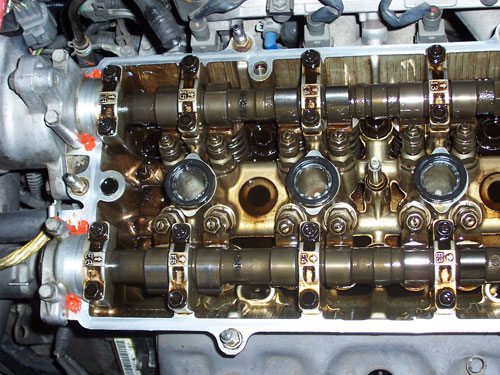

Remove the valve cover nuts, the ground wire, the breather hose, and the power steering bracket so that you can remove the valve cover. If the valve cover wont budge, tap it on the sides with a rubber mallet to break it free. Remove the spark plugs to make cranking the engine much easier.

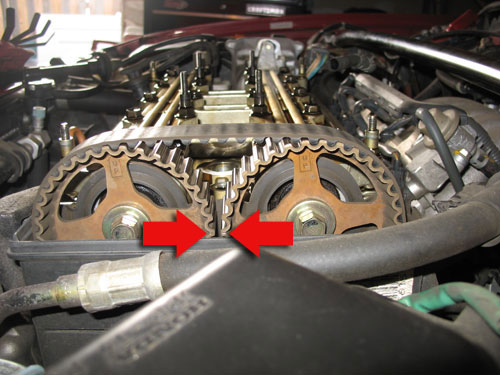

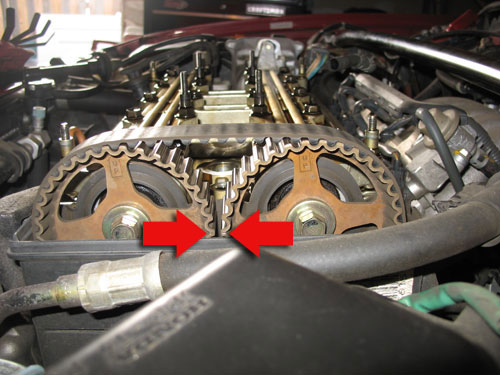

The cylinder closest to the cam sprockets is #1. The sprockets have markings on them to indicate when #1 is at tdc. The arrows will be pointing up and the markings on the sprockets will be aligned. For doing a valve adjustment, it doesn't have to be perfect. It just has to be close enough that the cam lobes aren't pushing on the valves.

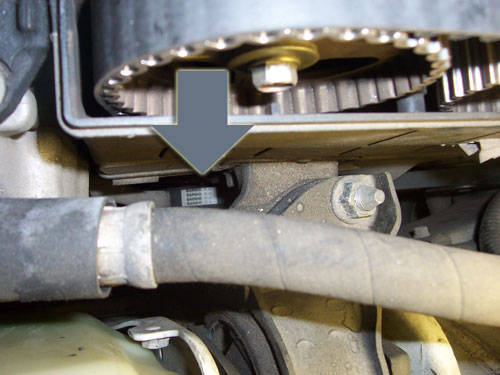

And just for confirmation the pointer on the timing belt cover will be pointing at the white mark on the crank pulley. Again, for a valve adjustment, it just has to be close.

Method

Now here is the method that guarantees that you get a good result even if you have no experience judging the amount of drag a feeler gauge should have.

When you check the valve clearance specs (found on the emissions label on the underside of your hood), it will have a high side and low side. You will get the most performance by setting all your valve clearances to the low side. You also want all your valves to have exactly the same clearance. If you have this performed by a mechanic, they might not touch a valve that is within that range. So you end up with an unbalanced engine.

For the B18C, the low side of the spec for the intake valves is .006 of an inch, and the exhaust is .007. The method is to try the next larger gauge to make sure it doesn't fit. So try .007 on the intake and .008 on the exhaust.

First loosen the valve jam nut, slide the feeler gauge in (low side of the spec), tighten the valve clearance until you can't pull the gauge out, loosen it just a hair so the gauge slides out with some drag. Put the feeler gauge in place again and tighten the jam nut. Slide the feeler gauge out again and try the next larger gauge +.001. It should not fit. For example on the intake valves the .006 should slide in with some drag but the .007 should not be able to slide in.

Torque Changes the Clearance

When you torque the jam nut, it may change the valve clearance. So it's important to get the torque just about right using the special tool, then check the torque with a torque wrench. Then recheck the valve clearance before you move on to the next valve.

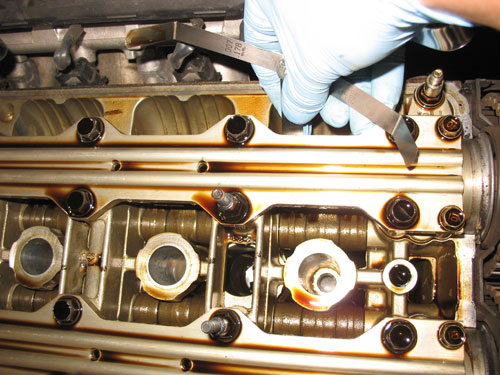

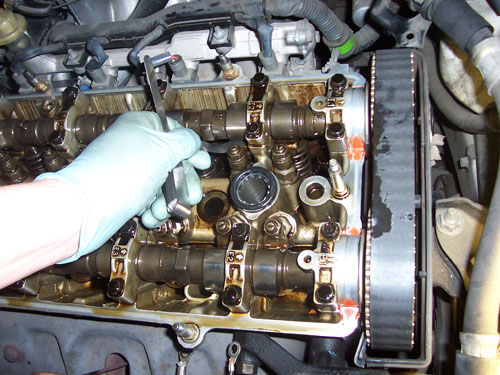

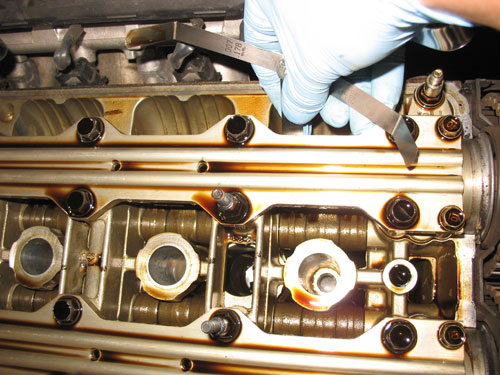

Checking one of the intake valve's clearance.

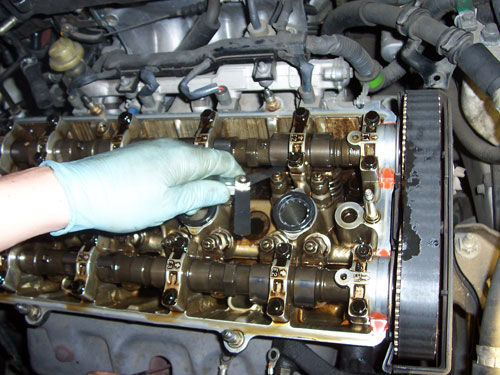

Checking one of the exhaust valve's clearance.

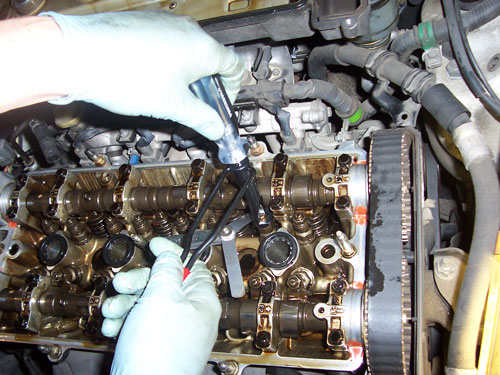

Adjusting the clearance and tightening the jam nut.

Torque the jam nut and recheck the clearance.

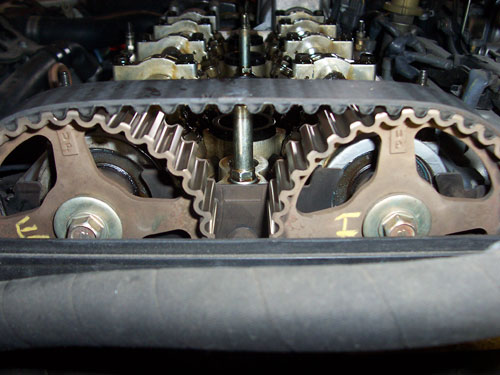

Now crank the engine so that the cam sprockets rotate 1/4th and the UP indicators are pointing to the front bumper. It's important to know that the cylinders don't fire 1, 2, 3, 4; they fire 1, 3, 4, 2. So after cranking the motor you now have cylinder 3 on tdc. So check cylinder 3 valve's clearances, not #2.

After adjusting #3, rotate the cam sprockets counterclockwise another 1/4th so the UP indicators are facing down. Now adjust cylinder 4's valve clearances.

After adjusting #4, rotate the cam sprockets counterclockwise another 1/4th so the UP indicators are facing right. Now adjust cylinder 2's valve clearances.

It's a good idea to recheck 1-4 again and get all the valve clearances as consistent as possible.

If you're replacing the valve cover gasket and spark plug tube seals, now is a good time to do that. Wipe of any oil and remove all of the old liquid gasket material. Apply the Hondabond to the valve cover gasket at the 90 degree angles. Work quickly because you only have a few minutes before it dries and you want the valve cover torqued down before that happens.

Torque the valve cover nuts to spec. They don't require very much torque and it surprises a lot of people when they snap them off.

Reset the ECU

It's important to reset the ECU afterward because the airflow through the engine will drastically change with a valve adjustment. On most Hondas / Acuras you simply remove the 7.5A ECU backup fuse found in the under-hood fuse box for about 15 seconds.

Wait for the Hondabond to Cure

Don't immediately jump in the car and drive away. You need to give it a couple hours for the liquid gasket to fully cure before you apply oil pressure to them. Otherwise you could have a leaky gasket and terminally filthy engine.

Last edited by suspendedHatch on Thu May 03, 2012 8:13 pm, edited 2 times in total.

You know who you are. You ride the short bus and you're totally helpless. Please don't work on your car!

You know who you are. You ride the short bus and you're totally helpless. Please don't work on your car!

I really don't get it if I leave in neutral and just turn it I should be fine and Also can I check wether not if I'm at tdc by removing the distributor cap and checking the brush? I'm not trying to take the easy way out I'm just not around that much available tools thanks

I really don't get it if I leave in neutral and just turn it I should be fine and Also can I check wether not if I'm at tdc by removing the distributor cap and checking the brush? I'm not trying to take the easy way out I'm just not around that much available tools thanks