- Sun Nov 17, 2013 2:45 pm

#338959

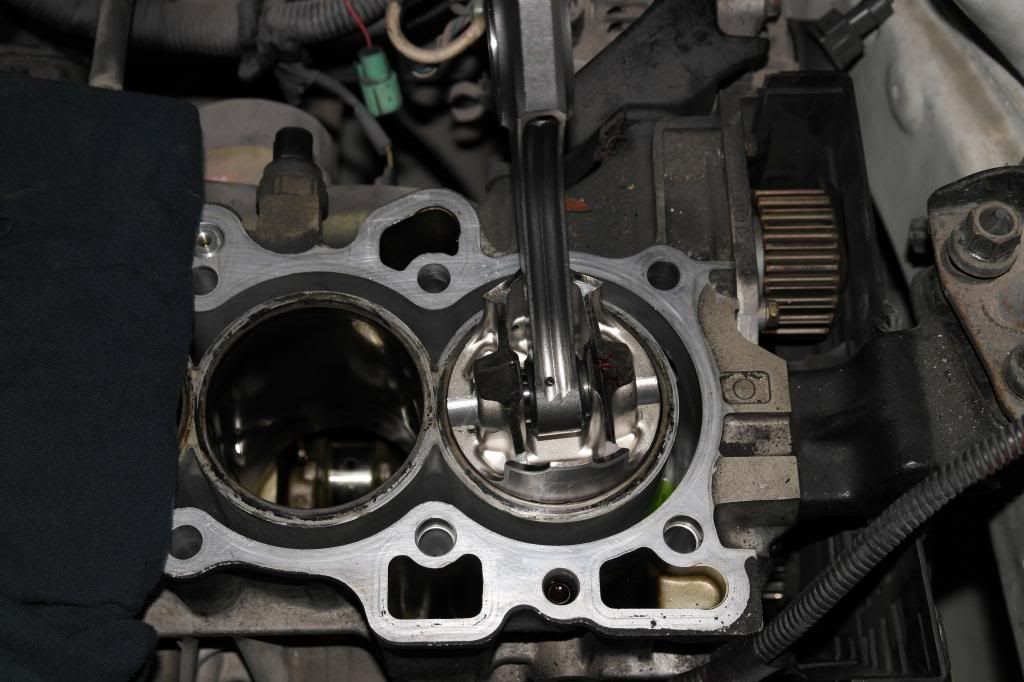

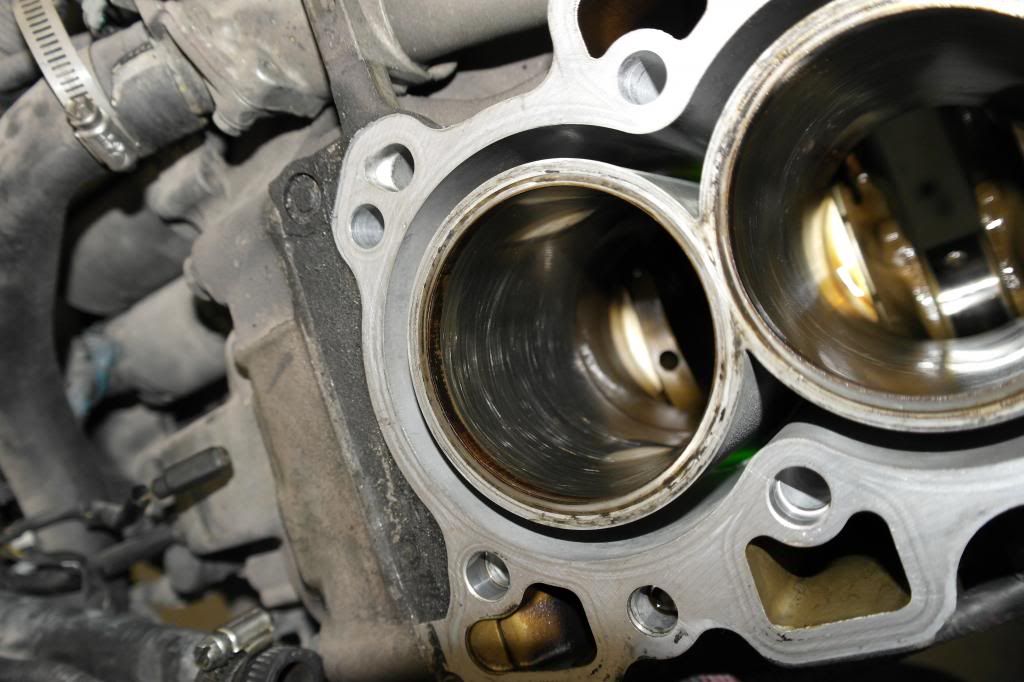

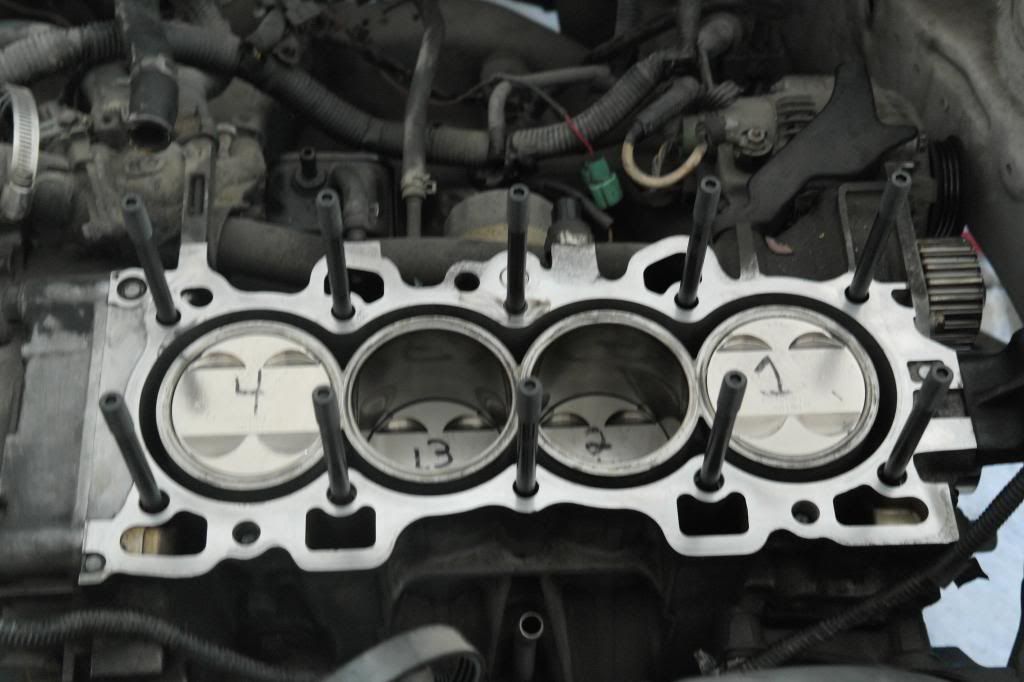

Few new tools later finally got the head bolts out. 1/2in drive is your friend for that. popped right off.

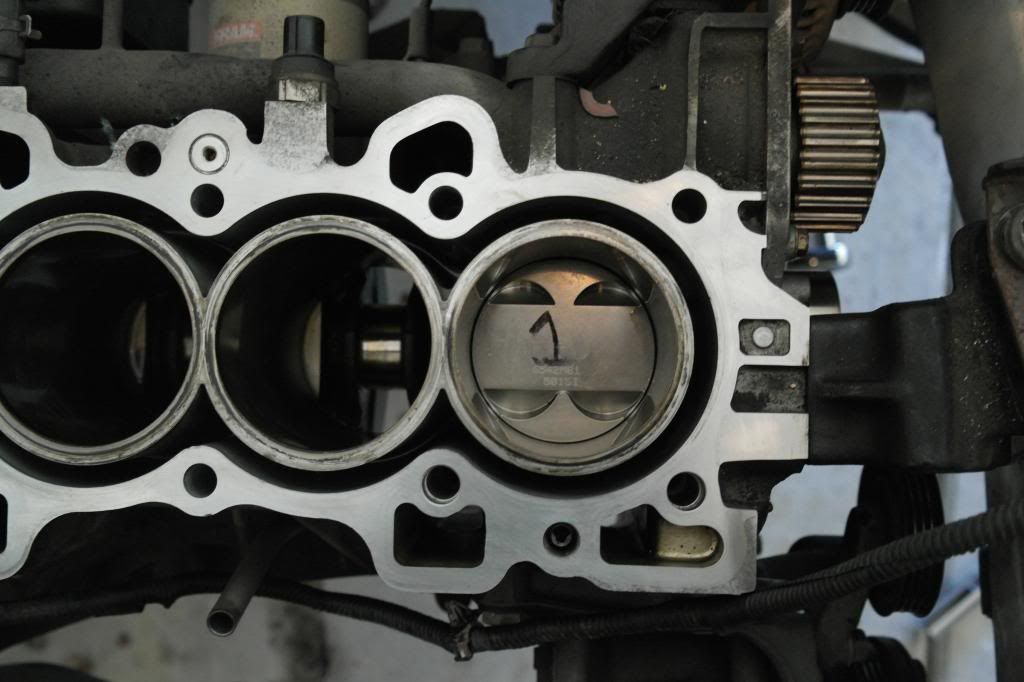

Next on the plate, remove oil pan and pull rods/pistons out of the top of block. hopefully once they are removed I wont have to do anything to the walls other then just measure and make sure they are in spec and hone.

Next on the plate, remove oil pan and pull rods/pistons out of the top of block. hopefully once they are removed I wont have to do anything to the walls other then just measure and make sure they are in spec and hone.

I don't play games, I quit first grade because of recess!!!