- Mon Dec 26, 2011 7:45 pm

#287114

Im new to the site and thought I would share my build. I have had this car first as a DD for about 7 years before I took it off the streets for good the last 2.

I hope this may be a help for people looking at building an actual race car.

Comments good or bad welcome.

The class is Super Touring Light and allows motor swaps so its similar to NASA's H classes. This is more of a rebuild/makeover of my GSR build so I used a few of those photos too. I blew that motor up at the Redline time attack at Sebring which was a real bummer. I luckily saved my old b18b block from my old ls/vtec so that was the cheapest rebuild scenario for me. The plan is to build an n/a b18b within the specs of the class.

Motul brake and gear fluids, Hawk ht-10 pads, brake ducts from honda-tech user jbs :thumbup:, skunk2 rear camber, blox rear toe, brake duct hose, b&m race shifter with spherical bearing which is one of the nicest additions I have ever made, and Progress Coilovers with 500lb progress/800lb hyperco springs which has been an amazing setup for the price Progress Technology: Anti-roll bars, sport springs, coil-overs, camber kits and more since 1995!. I showed my koni/gc for comparison between the 2 coilover setups.

Fast Brakes ITR front brakes.

Brake duct hose routed to the shock fork.

http://circuit-racer.com/forums/f12/scca-stl-super-touring-95-honda-civic-hatch-build-34/

Hyperco are sweet and very high quality, skunk2 rear camber kit as well.

Sad face waiting for a new heart. That motor is now out of the car and I just need to get this finished.

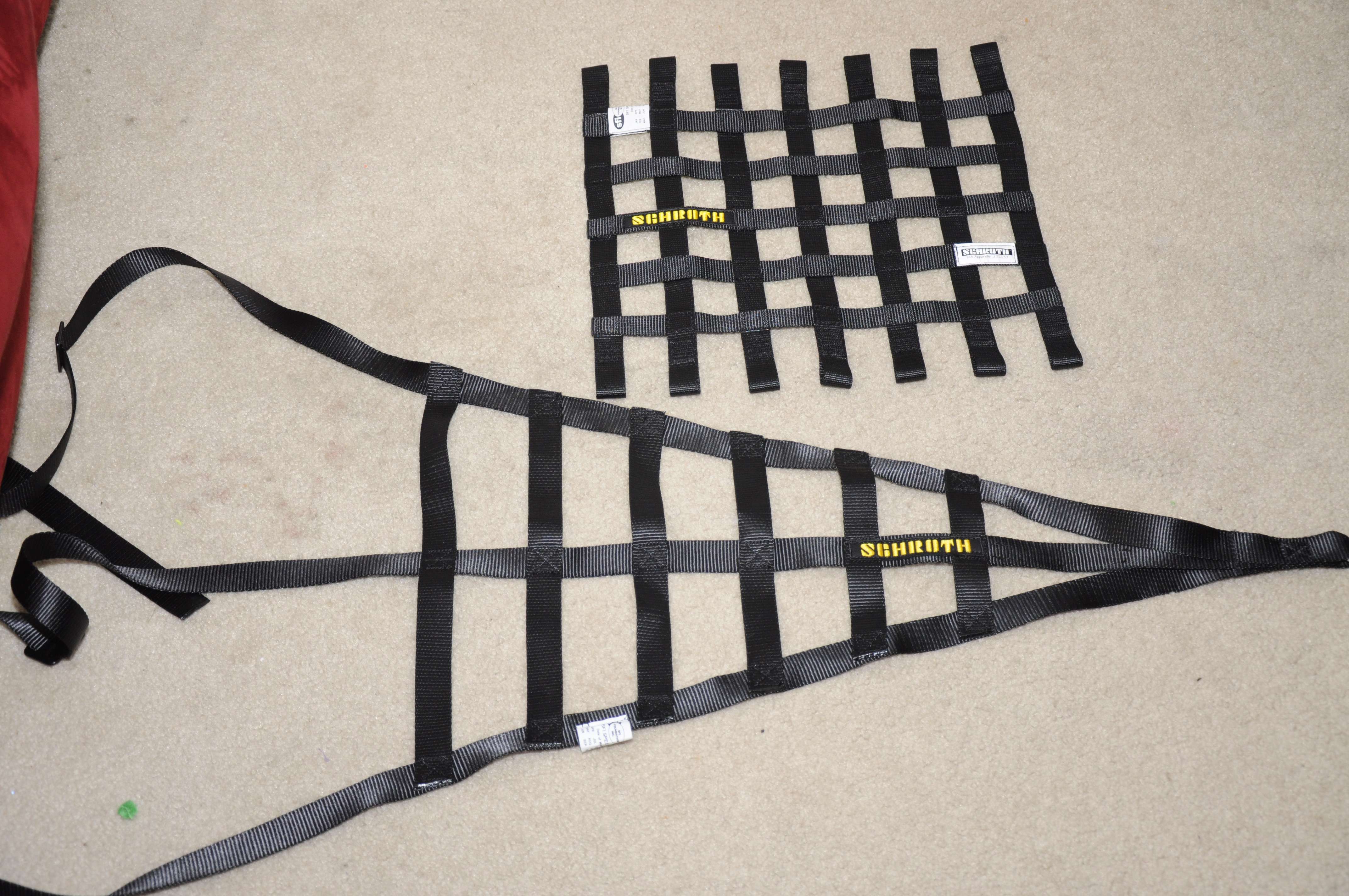

Racetech 1000, the crow harnesses are gone and Im replacing them with Schroth Profi 2 6 point

Some of the new DOM roll cage next to the seat. That slider wont be used and is against the rules.

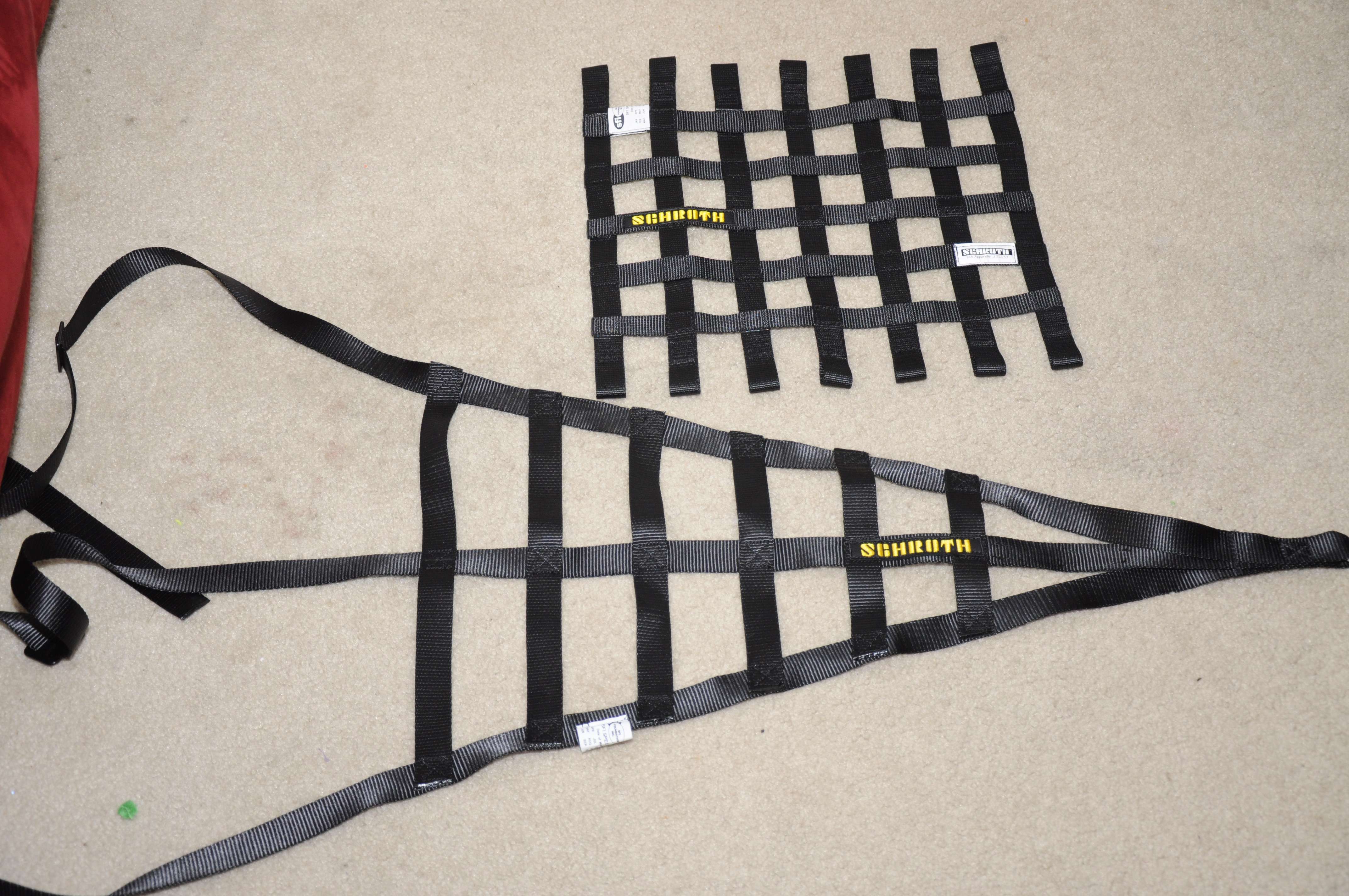

Schroth window net and side roll bar harness.

Engine work begins

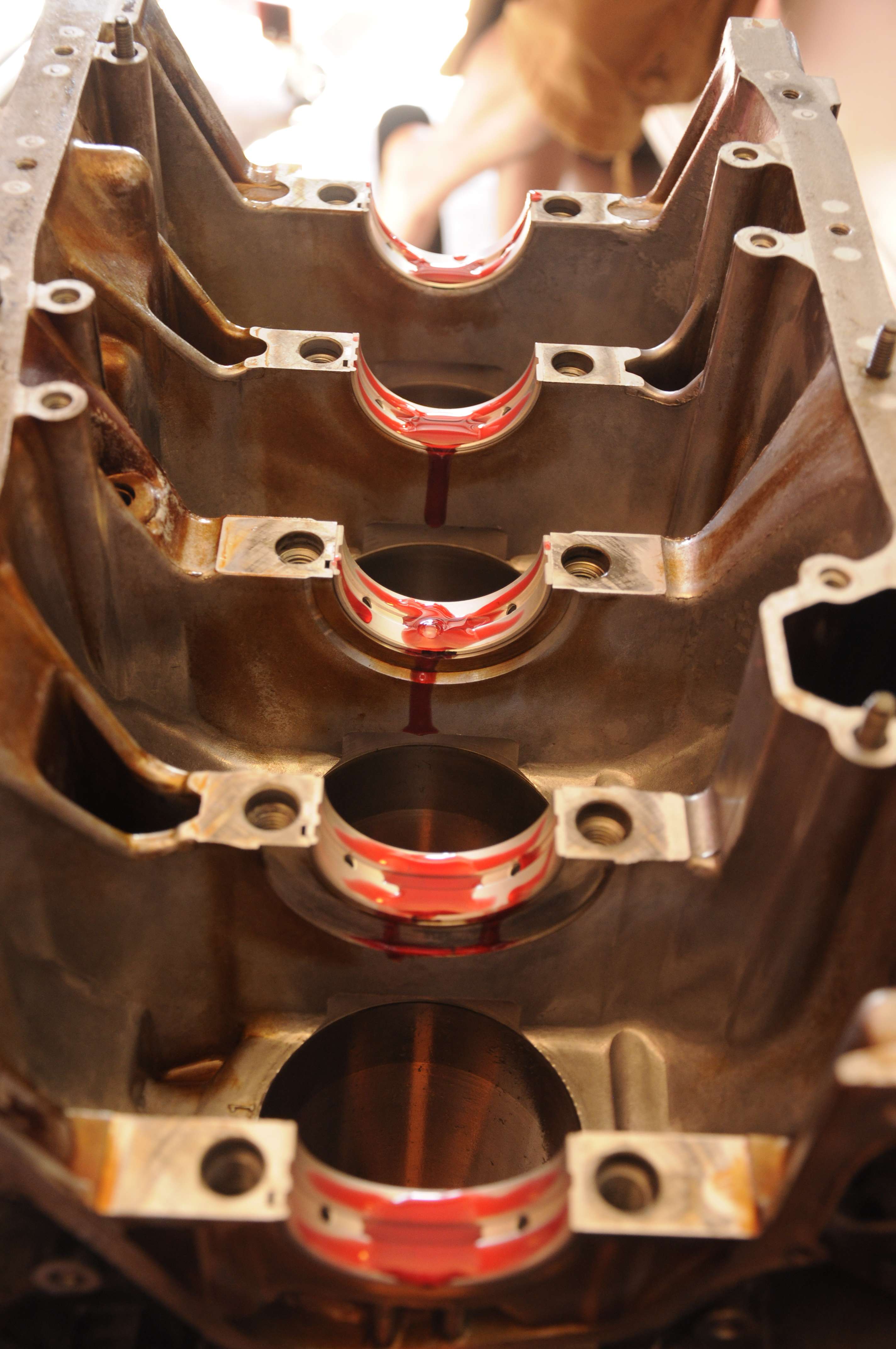

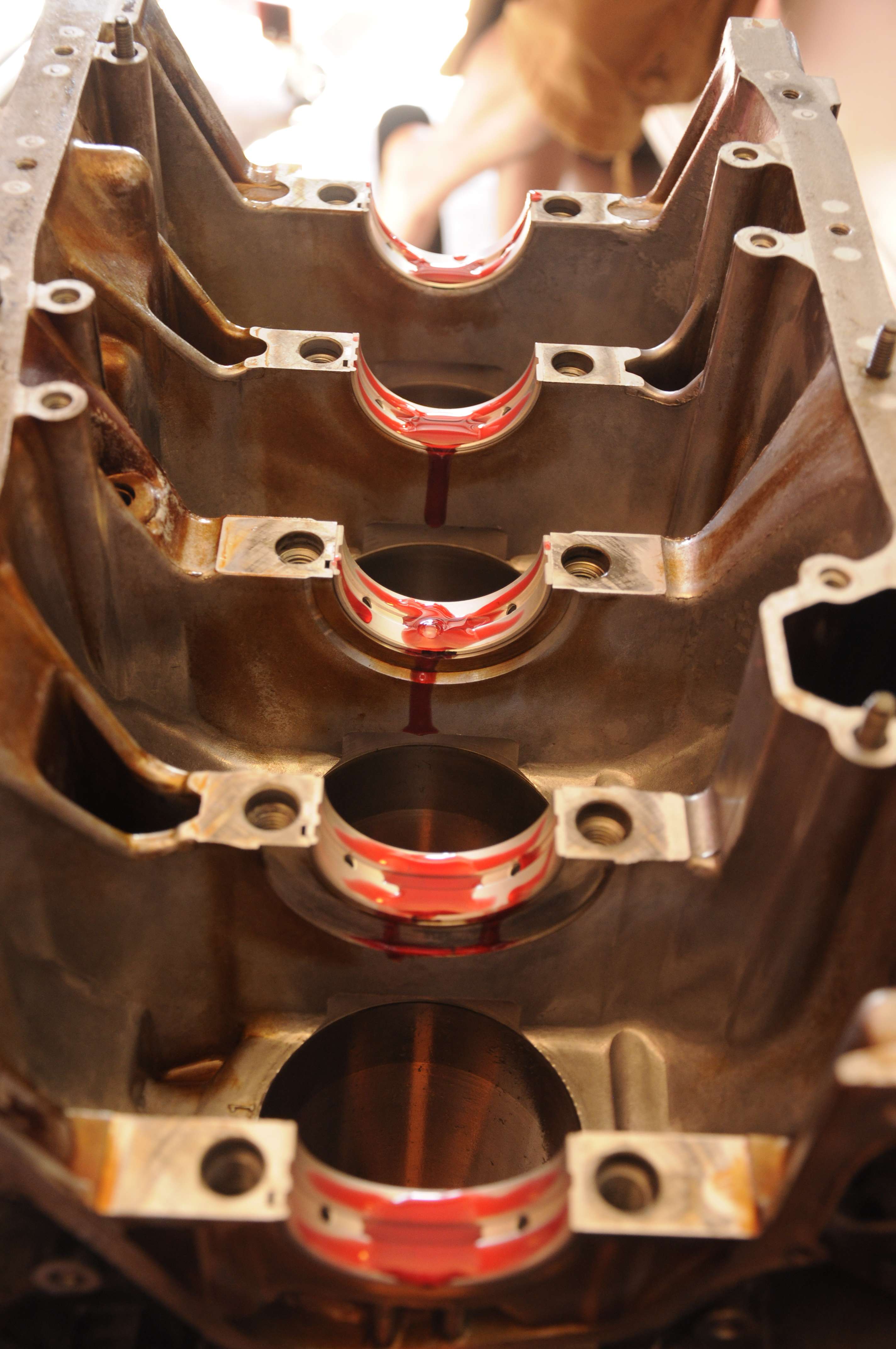

Adding some permatex lube to the new main oem honda bearings.

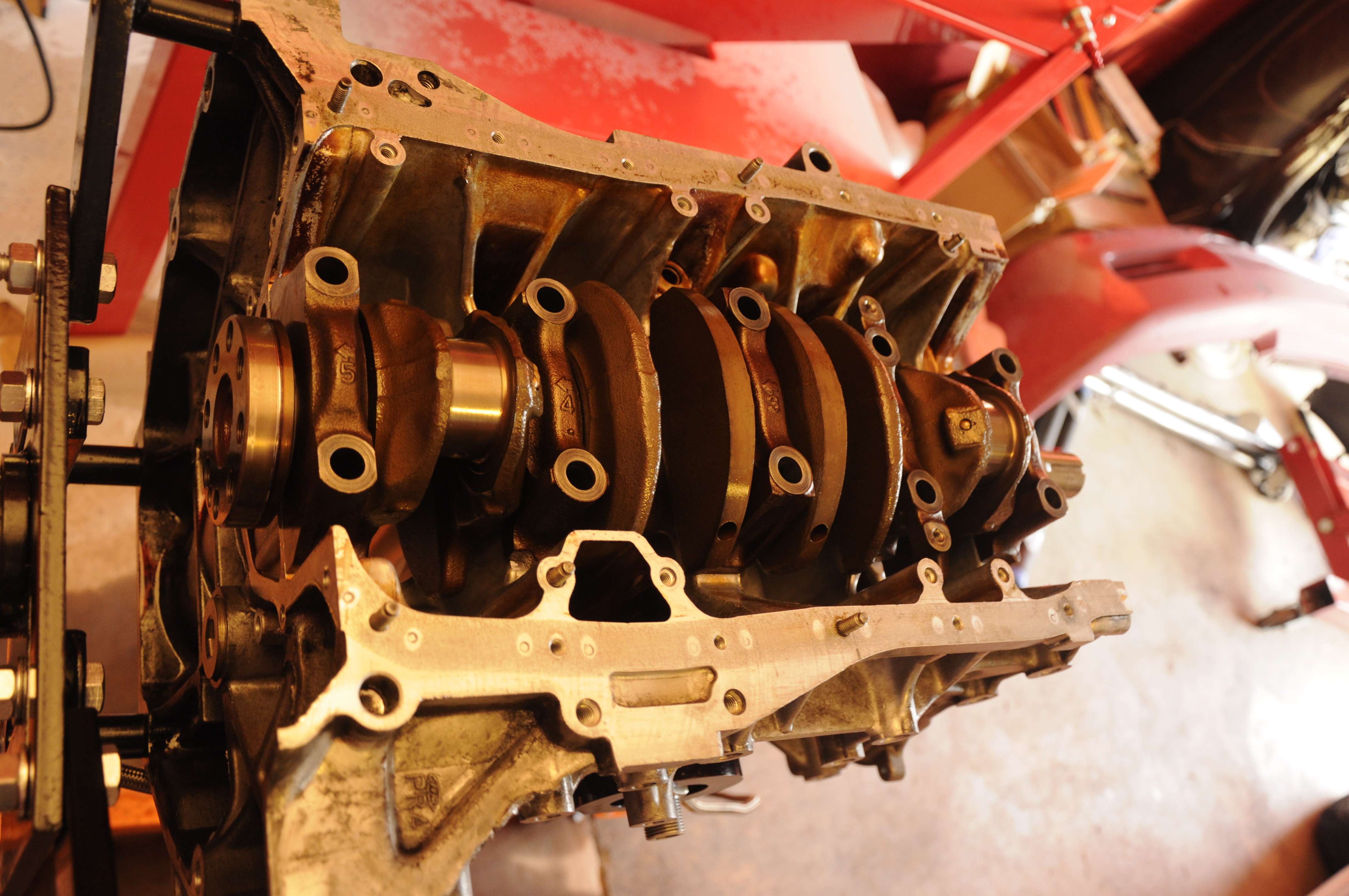

ARP rod bolts.

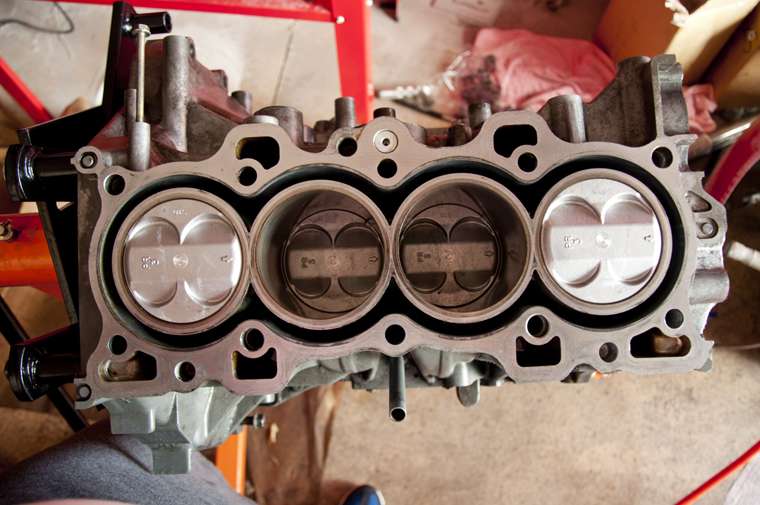

81mm RS machines USDM PR3 B16 pistons. The SCCA STL class so far allows 11.0.1 compression so this should put me right at or just under the compression using an OEM head gasket.

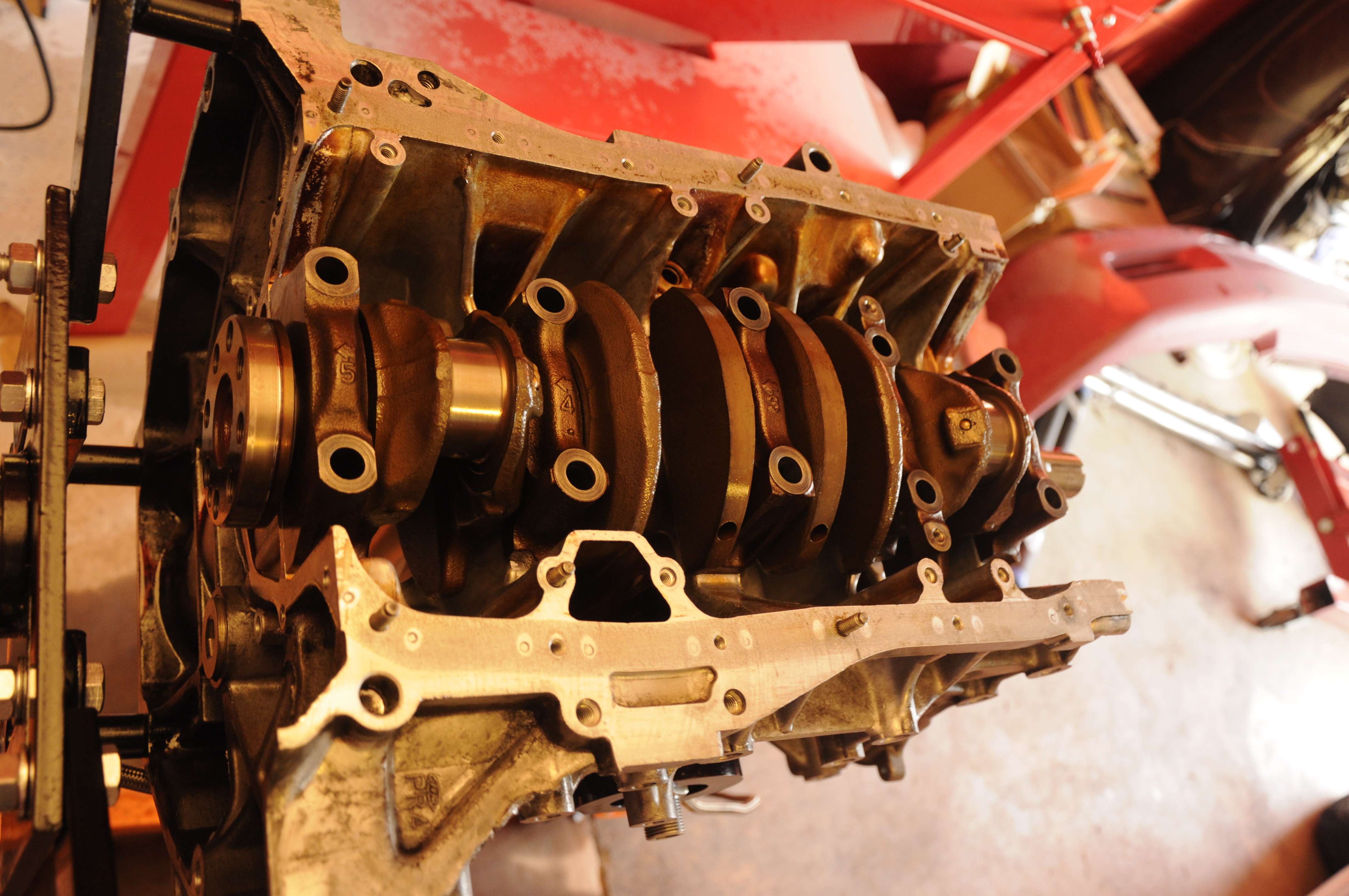

Main caps on just waiting for ARP main studs now....main caps are on backwards in this photo...oops I should know better.

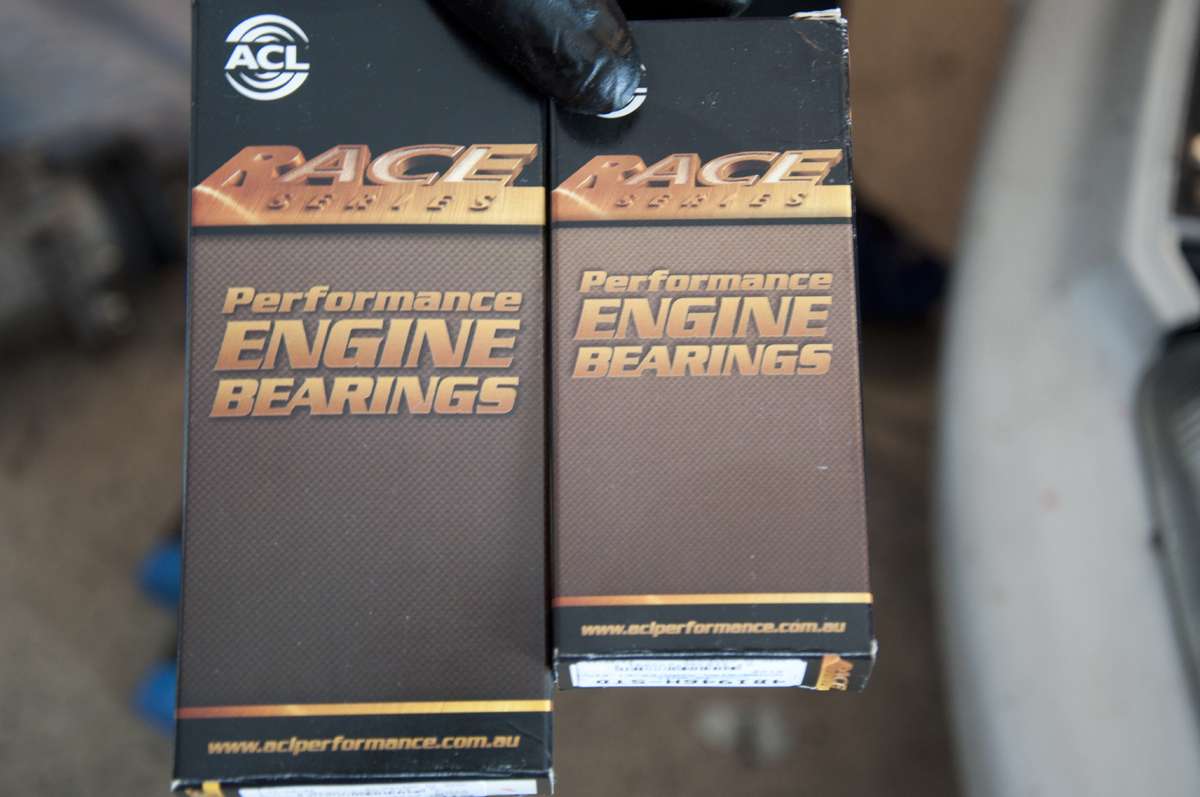

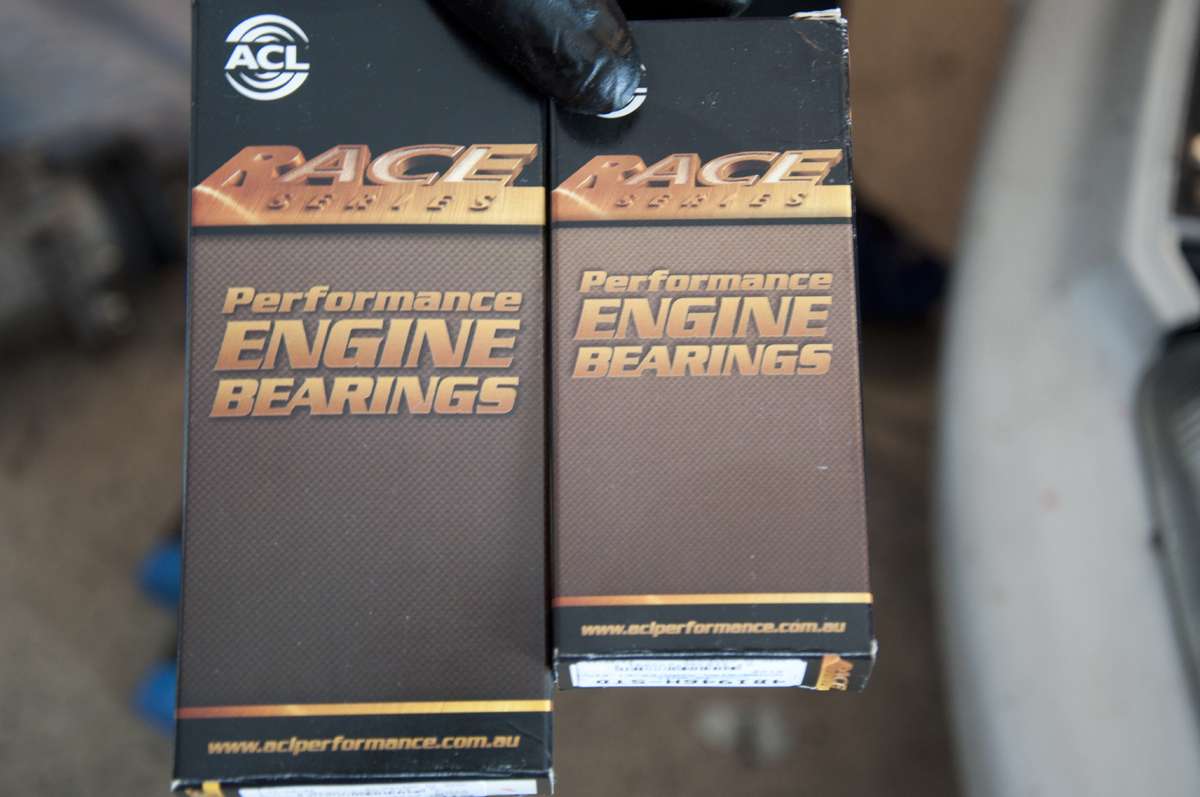

ACL race bearings main and rod end but Im only using the rod end because of clearance issues. The rods I have all have Green oem bearings which equate to about the same as a std acl rod race bearing. I went with oem main bearings because my block had a few different colors so I didnt want to go to a machine shop. All in all the crank looks perfect and the bearings showed minimal wear so I think this should be a good setup.

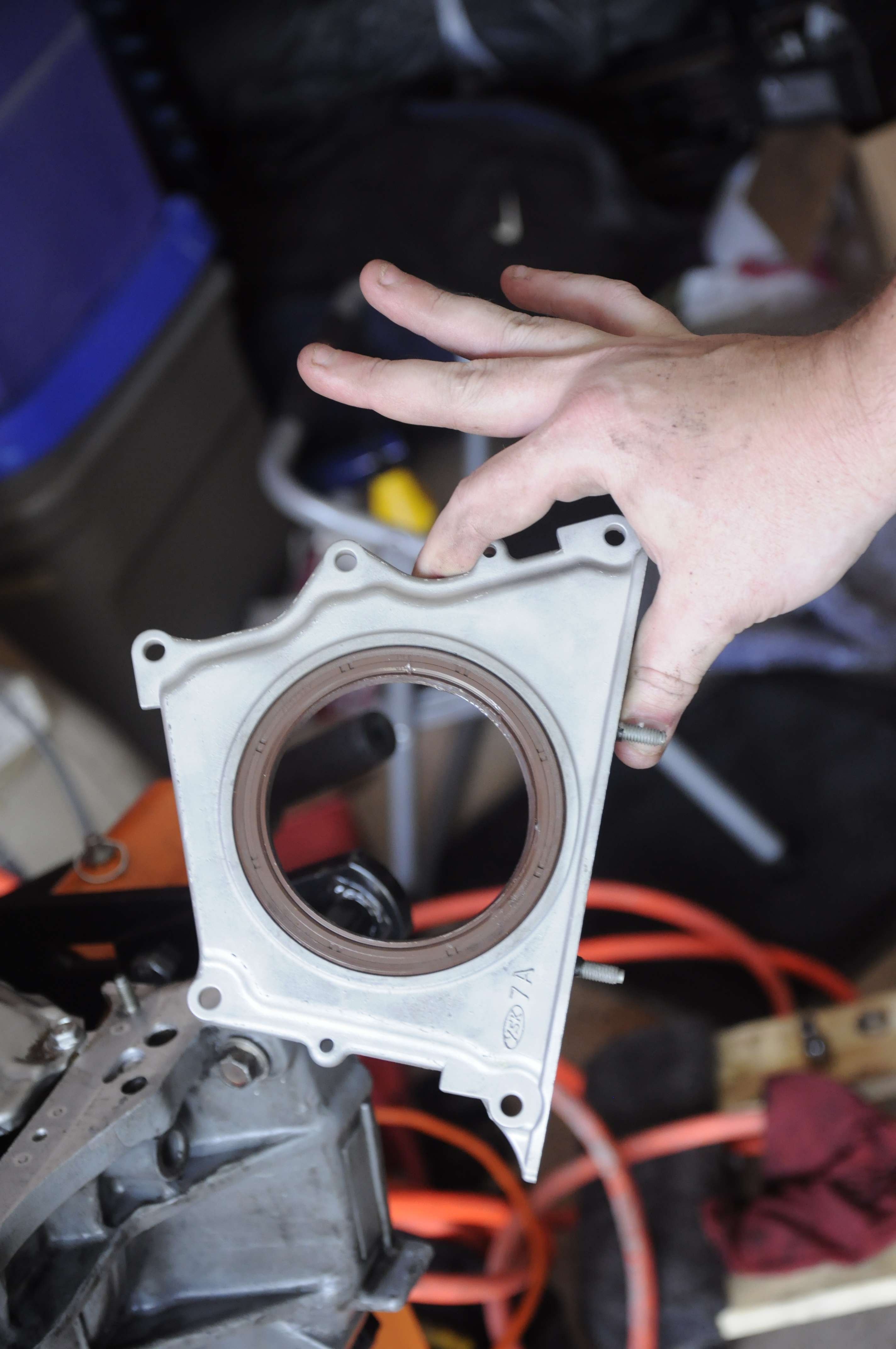

Oem honda gaskets, nuts and bolts. I also bought a brand new ob2 ls/gsr oil pump

Crappy iphone pics.

Schroth profi 2 6 point

Sparco tide gloves

Trip back from Honda, I also picked up some plasti gauge because I dont know if its the permatex pre lube or what but I can barely turn the motor over without a lot of force. I had to get new rings because I frigging broke a ring during the install.

I gave the cylinders a light honing because they looked pretty good already.

Measuring ring end gap which is right in between Hondas new ring limits of .20 -.35 these are .25

I will add some more stuff shortly.

I hope this may be a help for people looking at building an actual race car.

Comments good or bad welcome.

The class is Super Touring Light and allows motor swaps so its similar to NASA's H classes. This is more of a rebuild/makeover of my GSR build so I used a few of those photos too. I blew that motor up at the Redline time attack at Sebring which was a real bummer. I luckily saved my old b18b block from my old ls/vtec so that was the cheapest rebuild scenario for me. The plan is to build an n/a b18b within the specs of the class.

Motul brake and gear fluids, Hawk ht-10 pads, brake ducts from honda-tech user jbs :thumbup:, skunk2 rear camber, blox rear toe, brake duct hose, b&m race shifter with spherical bearing which is one of the nicest additions I have ever made, and Progress Coilovers with 500lb progress/800lb hyperco springs which has been an amazing setup for the price Progress Technology: Anti-roll bars, sport springs, coil-overs, camber kits and more since 1995!. I showed my koni/gc for comparison between the 2 coilover setups.

Fast Brakes ITR front brakes.

Brake duct hose routed to the shock fork.

http://circuit-racer.com/forums/f12/scca-stl-super-touring-95-honda-civic-hatch-build-34/

Hyperco are sweet and very high quality, skunk2 rear camber kit as well.

Sad face waiting for a new heart. That motor is now out of the car and I just need to get this finished.

Racetech 1000, the crow harnesses are gone and Im replacing them with Schroth Profi 2 6 point

Some of the new DOM roll cage next to the seat. That slider wont be used and is against the rules.

Schroth window net and side roll bar harness.

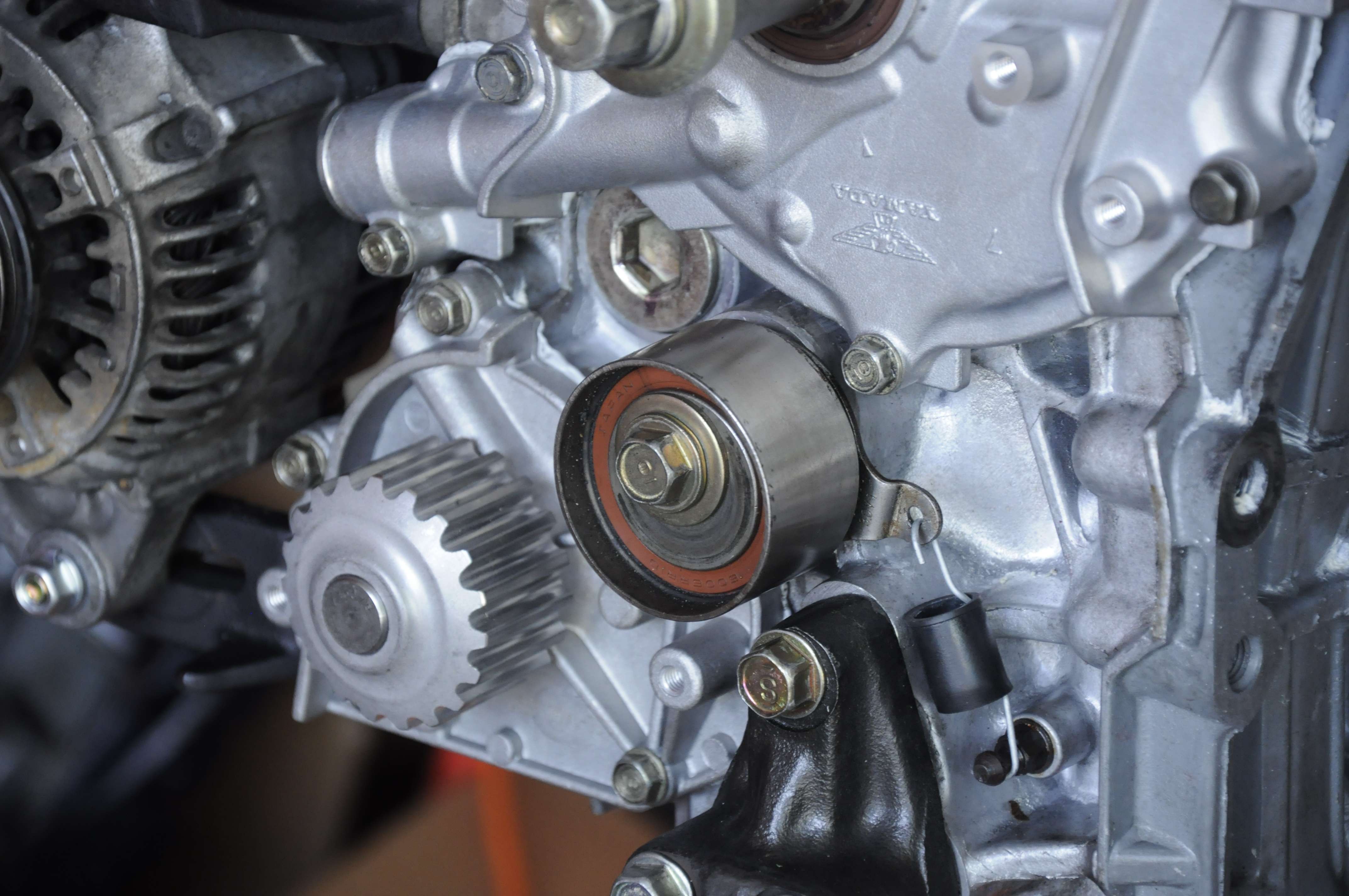

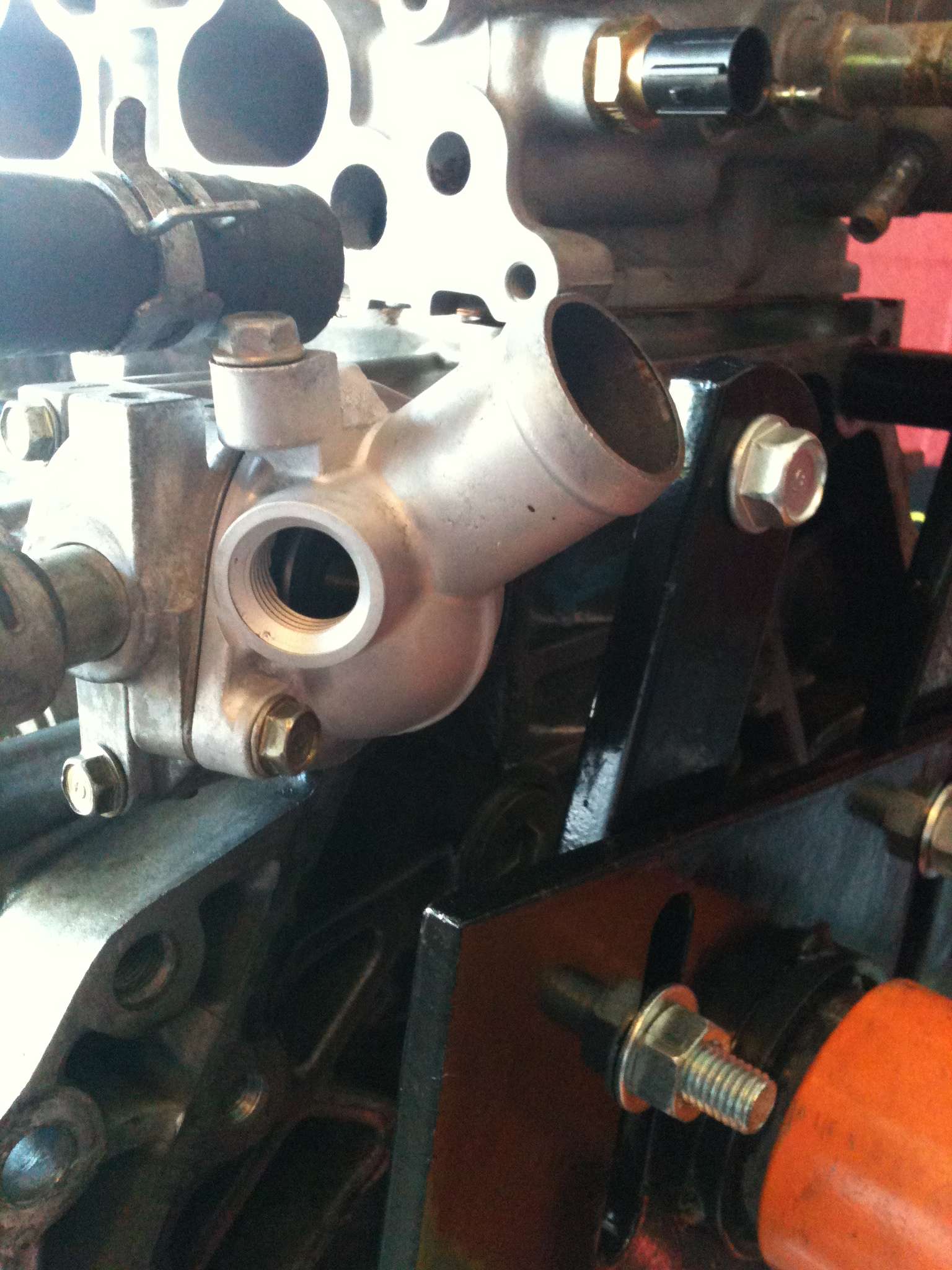

Engine work begins

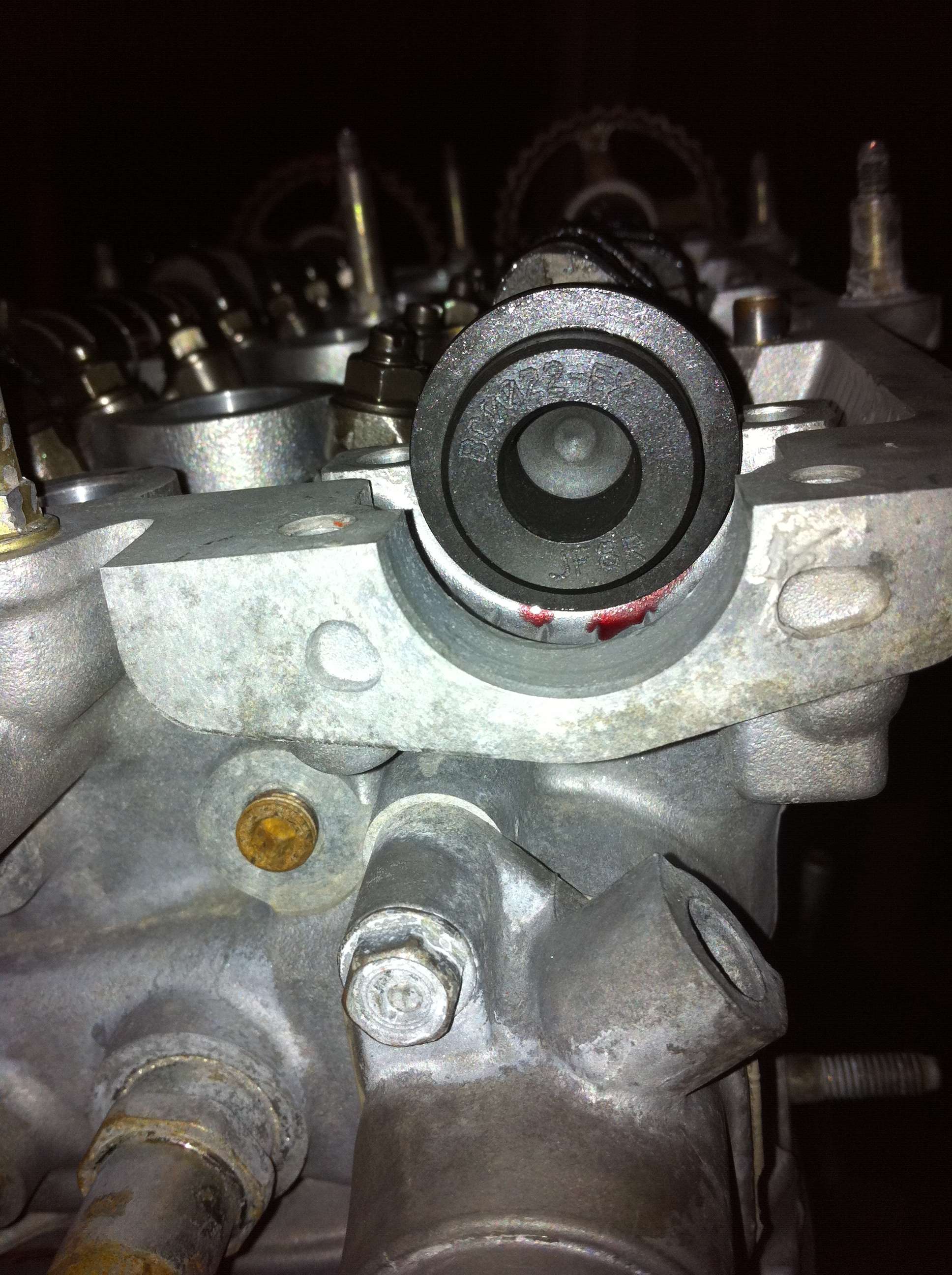

Adding some permatex lube to the new main oem honda bearings.

ARP rod bolts.

81mm RS machines USDM PR3 B16 pistons. The SCCA STL class so far allows 11.0.1 compression so this should put me right at or just under the compression using an OEM head gasket.

Main caps on just waiting for ARP main studs now....main caps are on backwards in this photo...oops I should know better.

ACL race bearings main and rod end but Im only using the rod end because of clearance issues. The rods I have all have Green oem bearings which equate to about the same as a std acl rod race bearing. I went with oem main bearings because my block had a few different colors so I didnt want to go to a machine shop. All in all the crank looks perfect and the bearings showed minimal wear so I think this should be a good setup.

Oem honda gaskets, nuts and bolts. I also bought a brand new ob2 ls/gsr oil pump

Crappy iphone pics.

Schroth profi 2 6 point

Sparco tide gloves

Trip back from Honda, I also picked up some plasti gauge because I dont know if its the permatex pre lube or what but I can barely turn the motor over without a lot of force. I had to get new rings because I frigging broke a ring during the install.

I gave the cylinders a light honing because they looked pretty good already.

Measuring ring end gap which is right in between Hondas new ring limits of .20 -.35 these are .25

I will add some more stuff shortly.

Last edited by known on Mon Dec 26, 2011 8:32 pm, edited 2 times in total.

[/img]

[/img]